Truck And Large Equipment Paint Spray Booths

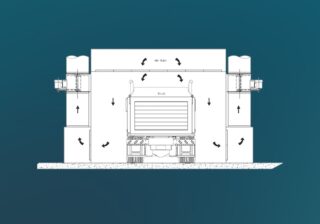

The Down Draft Paint Booth configuration is versatile, functional and efficient. With this design, air is pulled in from the top of the booth, travels down the sides of the booth and exhausts out through the floor. Excess paint, dust, and other contaminants are pulled away from the product as the air flows around it. This airflow pattern reduces the risk of contamination and is an excellent design for finishing large vehicles and equipment. Although the benefits of a downdraft are many, this configuration can be more expensive to install; Because the air is filtered out through the floor, the booth must be raised on a platform, or a pit must be installed underneath. With the Side-Down Draft method, the air is pulled into the booth the same way as the Down Draft configuration. However, it is exhausted out the bottom of the side walls – near the floor but not actually through it. With this method, most of the benefits of a Down Draft booth remain, but there’s no need to install a pit or a platform. This makes [...]