Production Systems offers high-quality paint booths and comprehensive finishing systems for the automotive industry. Our offerings include a variety of paint booths, pretreatment and surface booths, mix rooms, paint kitchens, and ovens.

With a focus on advanced engineering and paint technology, Production Systems designs and manufactures automotive paint booths that are not only industry-leading but also efficient, effective, and adaptable to different coating types. The company’s high-performance booths are designed to fit the unique needs of each facility, whatever the size. With exceptional air flow, excellent controls, and high-end lighting, our booths enable professionals to achieve a flawless paint finish on vehicles. Production Systems booths are easy to install and maintain.

Cross Draft Paint Booths

Cross draft spray paint booths are an efficient way to produce a high-quality finish for the automotive industry. Air enters from the front of the booth, flows horizontally through the space, and exits through an exhaust plenum in the back of the booth. Cross draft booths are generally the most economical and are easy to integrate into a facility. This makes them the most popular for a wide variety of environments, such as automotive. Considerations regarding this booth design include the position of the operator – making sure they are not in the way, disturbing the flow, and the distance that dust or contaminants that may be present must travel before it exits.

Down Draft Paint Booths

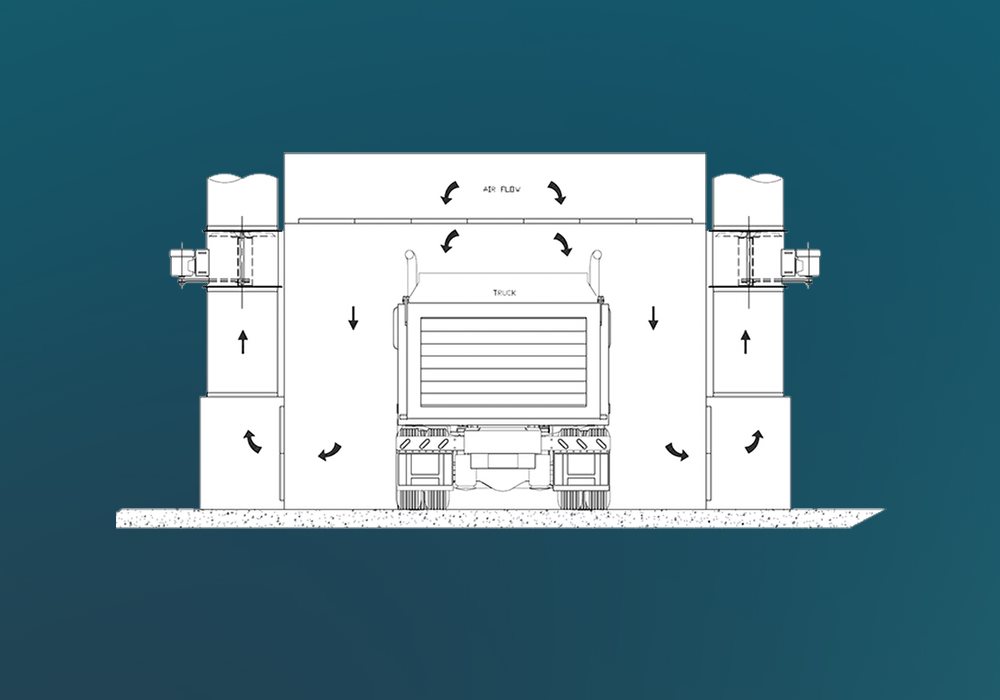

With a down draft, also known as vertical draft system, air enters from the top of the booth and filters out through the floor of the booth. Air flows around the product and pushes dust, contaminants, and excess paint down, away from the product. The air introduced into the system flows through a filter positioned in the booth ceiling providing clean air to the coating area.

Down draft booth design generally creates a cleaner process and is often thought of as the best air flow method. The operator is out of the line of air flow and risk of contaminating the product is reduced. The disadvantage of these systems is that they are more expensive due to the air flowing out through the floor; the booth must either be raised or a tunnel or pit must be placed underneath.

Contact us to learn about our other air flow and ventilation systems and the options we offer for your specific application. Get started and enhance productivity and quality in your automotive coating operation.