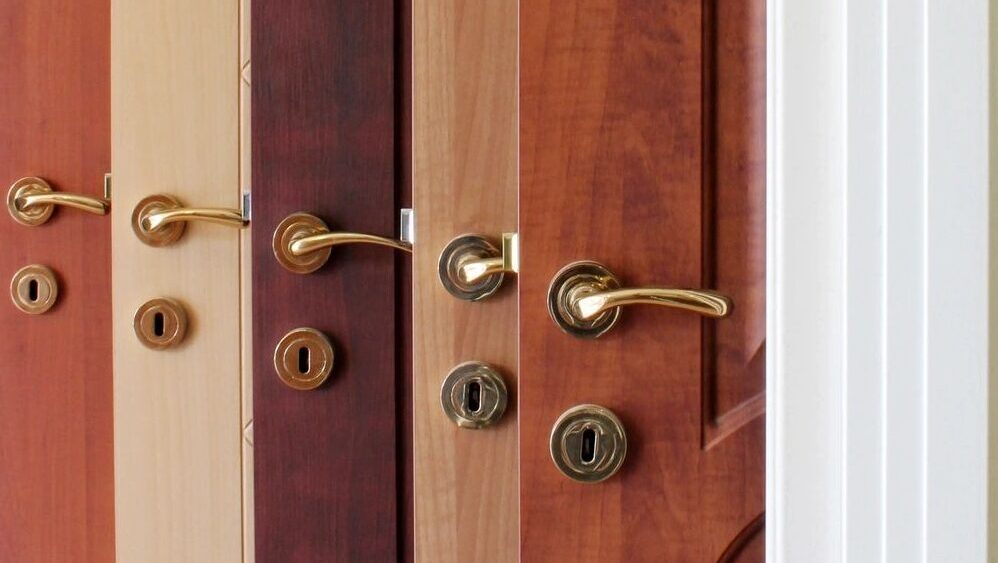

Linear spray booths are used to spray primer or a finish to flat straight items, such as door frames, doors, window frames, picture frames, moldings, flooring, and more. However, these spray booths can be adjusted to handle shapes and angles. They offer a fast and efficient way to finish larger volumes.

Common materials that are coated include:

- Wood, plastics, composites, metals

Commonly used materials that are applied include:

- Various paints, polyurethane, sealants, coatings

Automatic linear spray machines consist of:

- the control panel

- air adjustment gauges

- conveyor for transport

- piece sensor

- spray guns

- recovery troughs

- filter unit

- exhaust fan

- pump

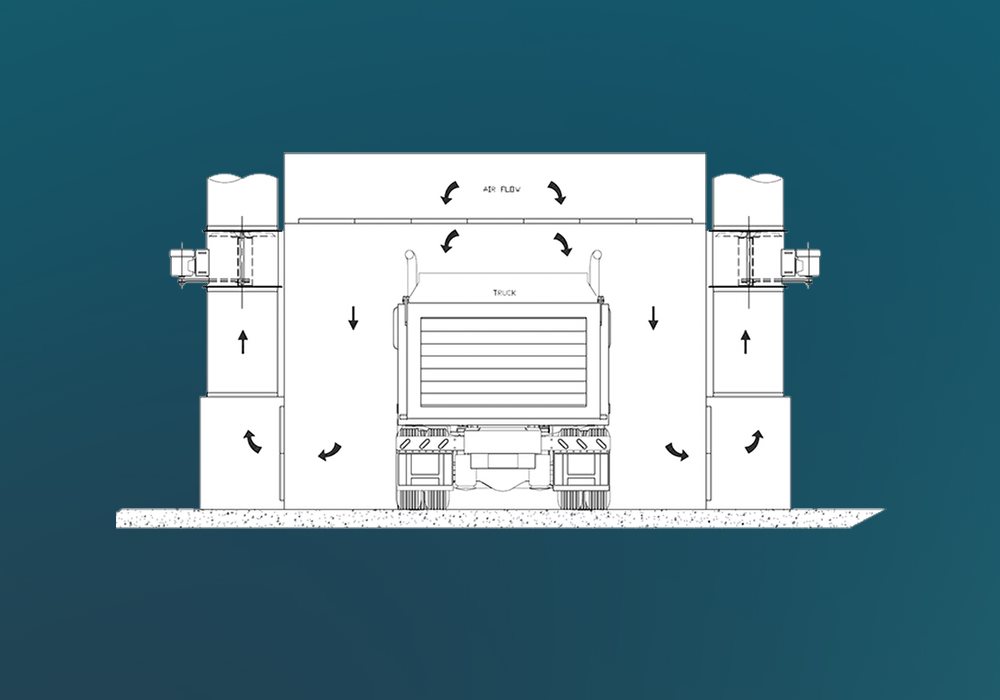

The conveyor in a linear paint spray booth transports the work item to the spray guns. When the item is in position, the spray guns are triggered to apply the coating. When the item moves away from the guns, the guns automatically turn off until another piece is in place. This ensures the spray is only on when an item is in position, minimizing wasteful overspray and taxing the filtration system.

Linear spray booths generally include three to six spray guns to paint pieces that are conveyed through the machine. Beneath the spray guns is a recovery trough that is made to capture the overspray and recover as much of the it as possible. The remaining overspray is pulled through the filter unit that is exhausted out of the machine.

Most paint sprayers utilize three types of spray guns: conventional, HVLP, and air assisted airless. Spray gun setup takes three factors into account: the distance and angle of the spray tip in relation to the work item, the spray gun fan pattern (flat, round, elongated oval, etc.), and the amount of fluid that is released.

For best results, the spray guns are positioned so that the pattern from the spray gun covers the work item uniformly with the least number of guns. However, one gun may not always achieve the desired coverage. In these cases, incorporating additional guns to cover various parts of the work item are needed.

Setting up the machine requires the following:

- Setting up the machine requires setting up the sensors. The sensors alert the machine of the item that’s coming in and going out. As mentioned earlier, this means the spray will turn off when there is not an item in position that needs to be sprayed.

- Conveyor speed must then be set. Speed is generally set to meet production requirements.

- Air and fluid regulators are set for the air pressure and fluid quantity of each gun.

- And finally, the spray gun orientations are set.

The guns are manually tested and fine adjustments are made. The machine is now ready to spray.

In today’s finishing processes, linear automatic paint sprayers are ideal for the application of coatings to manufactured items with consistency, uniformity and speed. Our linear spray booths at Production Systems have front access to adjust and maintain mounted spray guns. All booths are mounted with adjustable guns to provide maximum spray coverage. And our booths are completely enclosed with overspray chambers and a retractable exhaust tray for easy clean up.

Contact us today to learn more about our Linear Automatic Spray Booths, as well as our other products for industrial finishing.