When it comes to air flow in a paint spray booth, the idea is to move air around the object being painted out of the area, so that overspray does not get deposited back onto the new coating. Advantages and disadvantages of various types of drafting systems result from the direction of the air. Since the air must flow from one end of the booth to the other, it stands to reason that in some instances dry overspray will end up on an area that has not yet been painted, or even worse, an area that has. A good painter knows how to work within the parameters provided by the system to provide a flawless finish, however, it takes effort.

Turbulent Airflow

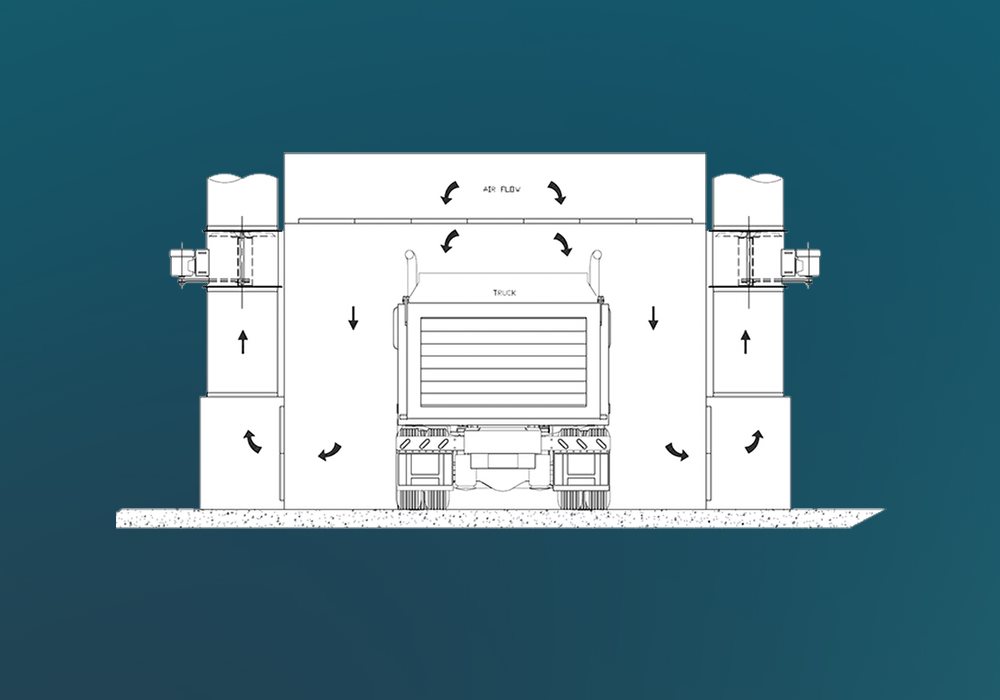

Some types of booths create turbulent airflow. Turbulence is created when two banks of air turn and collide with each other on their way to the other side of the booth. This happens again when the air has to separate in two to be exhausted.

Turning Air

In booth styles, air comes into the booth and must turn in order to exit the booth. In the location where the air turns, the air particles can start to circulate, creating problems for the painter. The circulating air may deposit dry overspray back onto the newly coated areas.

Even Movement Of Air

Another style of paint booth, the down draft, introduces air through the ceiling of the booth and exhausts it through the floor. This design has become the preferred method for the automotive industry, due to its ability to draw air evenly around the vehicle. This top to bottom air flow has many advantages.

Production Systems can help your company analyze the advantages and disadvantages of the various types of paint spray booths and decide what is best for your application. Contact us to learn more about us and our finishing systems.