Paint spray booths are designed to keep dust, dirt and moisture away from paint jobs being performed inside the booth. Occasionally you might find contaminants in your paint jobs, the reason is typically a dirty or poorly maintained paint spray booth. Establishing a regular cleaning and preventative maintenance routine can help keep your booth efficient and production costs low. Below are maintenance tips and best practices that can significantly extend the lifespan of a paint spray booth and reduce the risk of contamination by dust and dirt on your jobs.

- Limit traffic in and out of the spray booth. Less traffic means less chance for contamination.

- Have all painters wear a lint-free painter’s suit and headcover and store these suits in a clean area.

- Keep the spray booth’s doors closed as much as possible. Place a specialized mat at the entrance of the booth to help workers keep their feet clean when entering.

- Keep the spray booth on and running when you are bringing in the objects to be spayed. This way, any airborne contaminants you bring in are drawn into the exhaust filters.

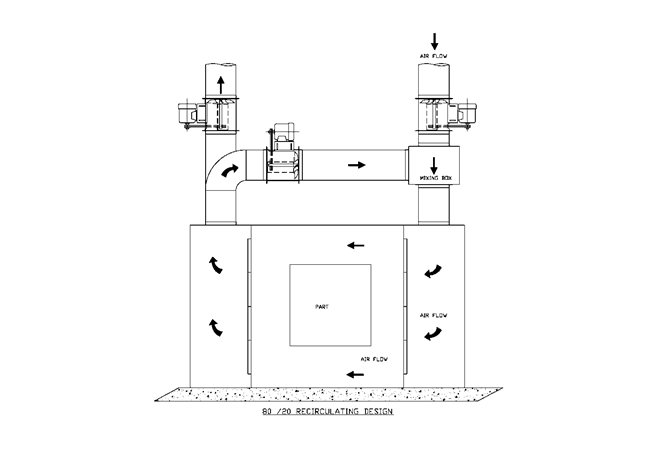

- Replace the air filtration filters regularly and use high quality filters. Filter maintenance is extremely important as they collects hazardous compounds and recycles airflow. Follow the booth manufacturer’s filter change schedule and clean the exhaust stack, plenum, duct and fan annually. A high-quality filter provides correct diffusion to prevent turbulence and inconsistent airflow. Each type of filtration needs to be maintained correctly to provide a safe environment.

- As a precaution, monitor when your filters need changing with a manometer. A clogged filter can throw off the balance of your paint booth. The manometer measures pressure differentials which indicate when paint booth filters are plugged and need to be replaced.

- Only equipment related to spray and finish applications should enter the booth. Do not leave any unnecessary items in the spray booth.

- Use a disposable coating on the walls and interior surfaces of the booth. Chemical coatings can be sprayed on surfaces and physical film linings can also be placed along the walls and floors to catch debris and overspray. The chemical coatings are designed to easily peel away or dissolve in water when it’s time for a replacement.

- Even after replacing the disposable coating and protective lining, all your spray booth surfaces should be regularly cleaned. Establish a cleaning schedule based on the type of booth, the nature of the spray operation and frequency of use. Use a sponge mop and solvent-based materials to break down paint on the spray booth’s floor and walls and clean paint guns and air hoses, and replace them when necessary.

- Clean the glass bulbs over the lights and replace burned out bulbs to ensure optimal lighting.

Following the tips above should help you keep your industrial paint booth clean and operating efficiently. Proper cleanup and maintenance is crucial for creating flawless finishes and also for providing a safe and efficient working environment for your employees.

Production Systems manufactures all types of paint spray booth systems. We can help you identify which booth is best for your specific application and then help you maintain it. Our engineers are here to help with any questions. You may call us at (336) 886-7161, or email us at info@productionsystems-usa.com for more information.