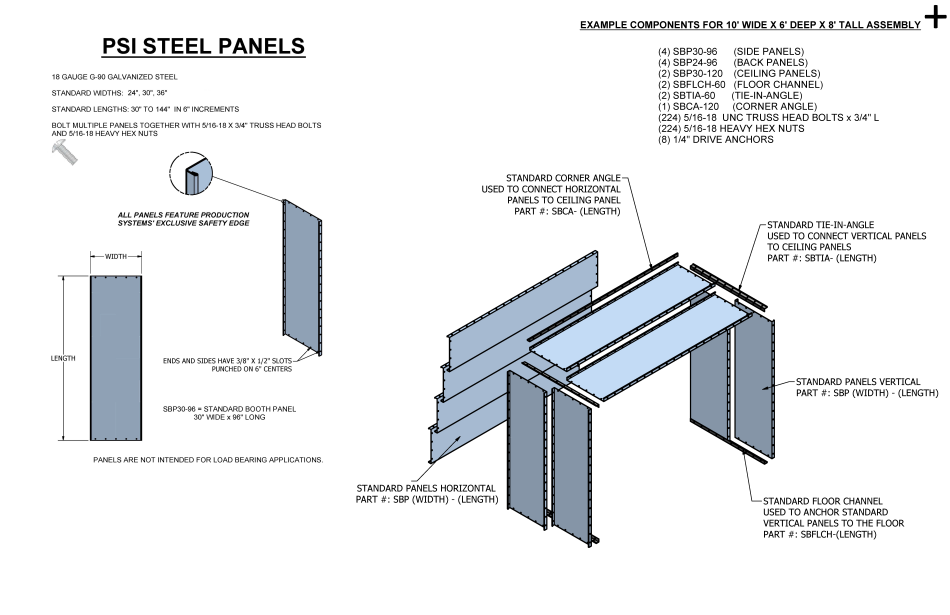

Booth Enclosures

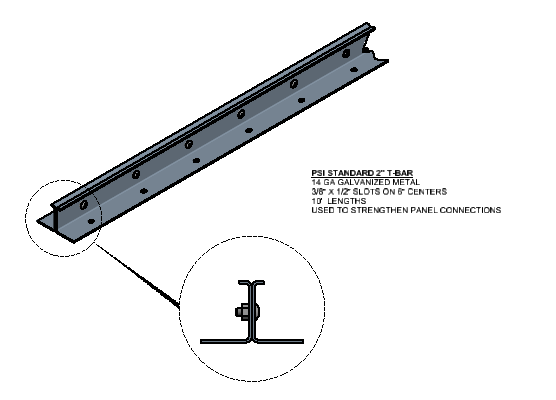

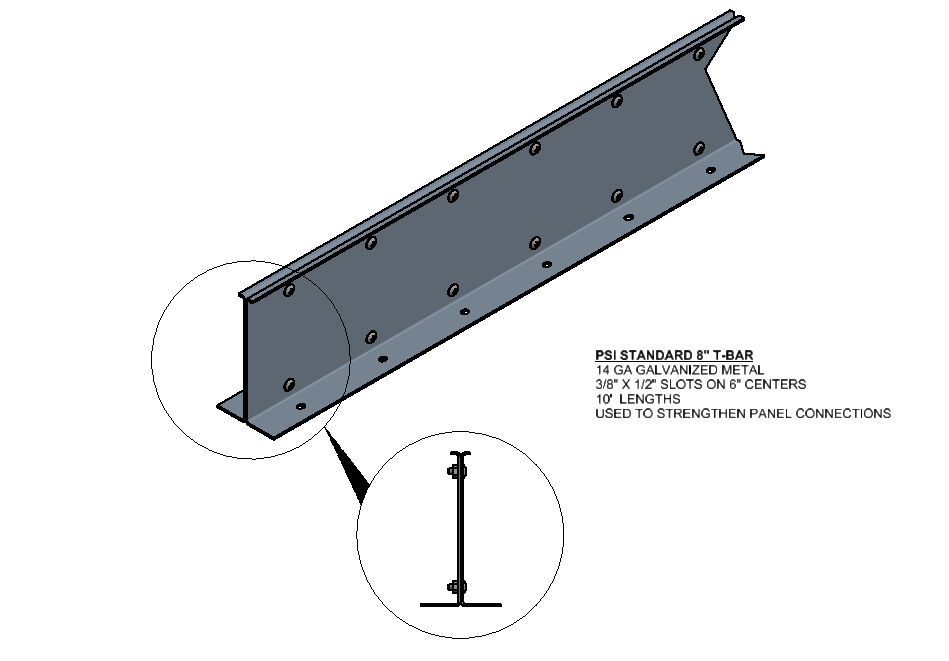

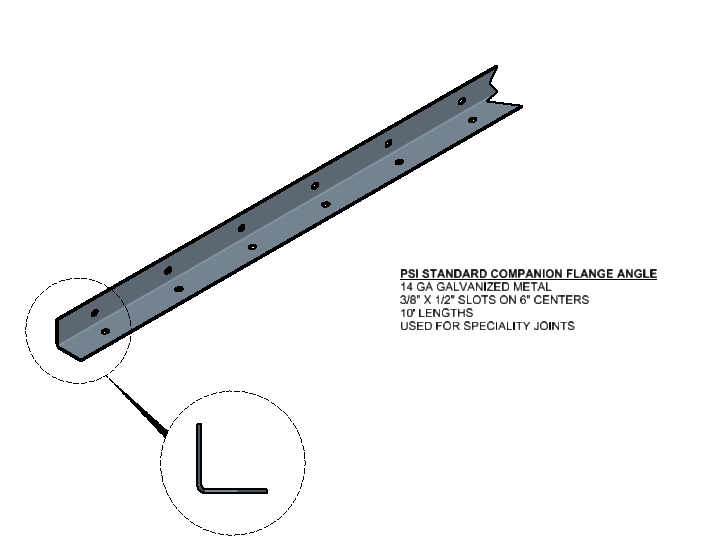

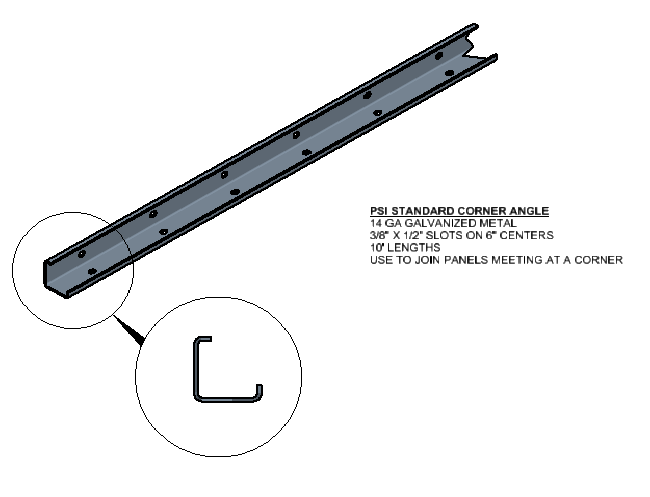

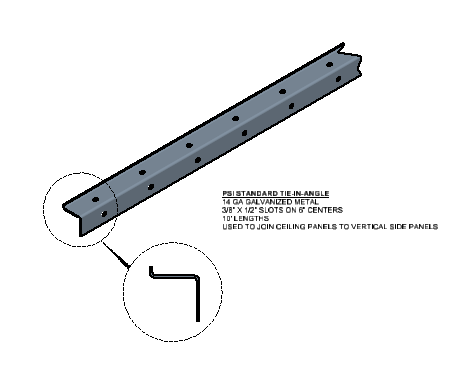

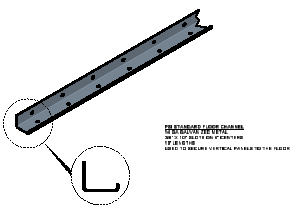

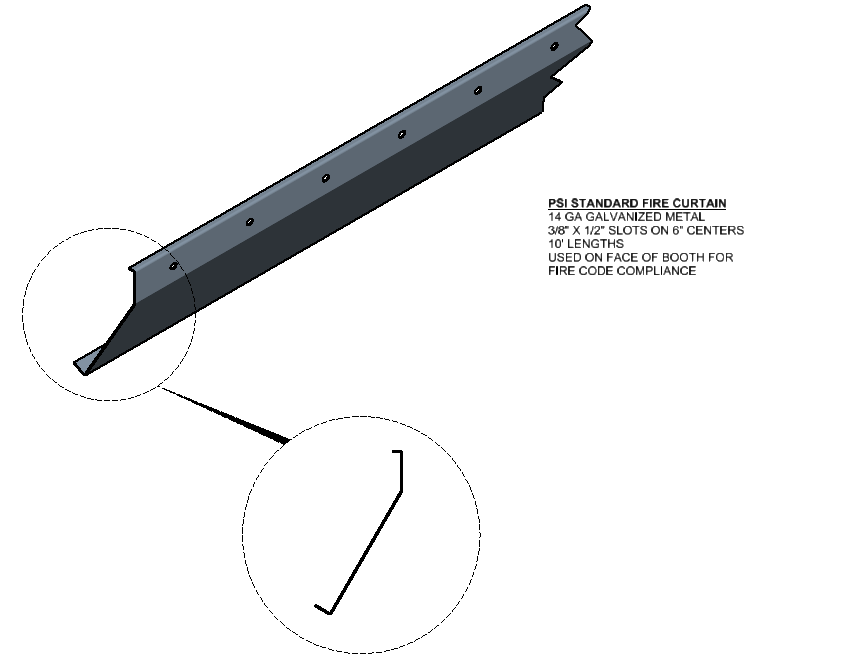

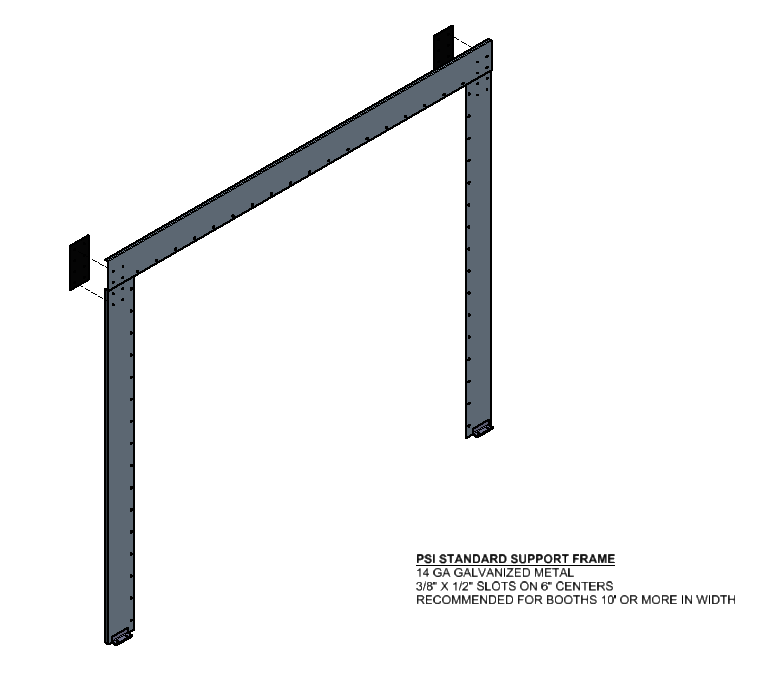

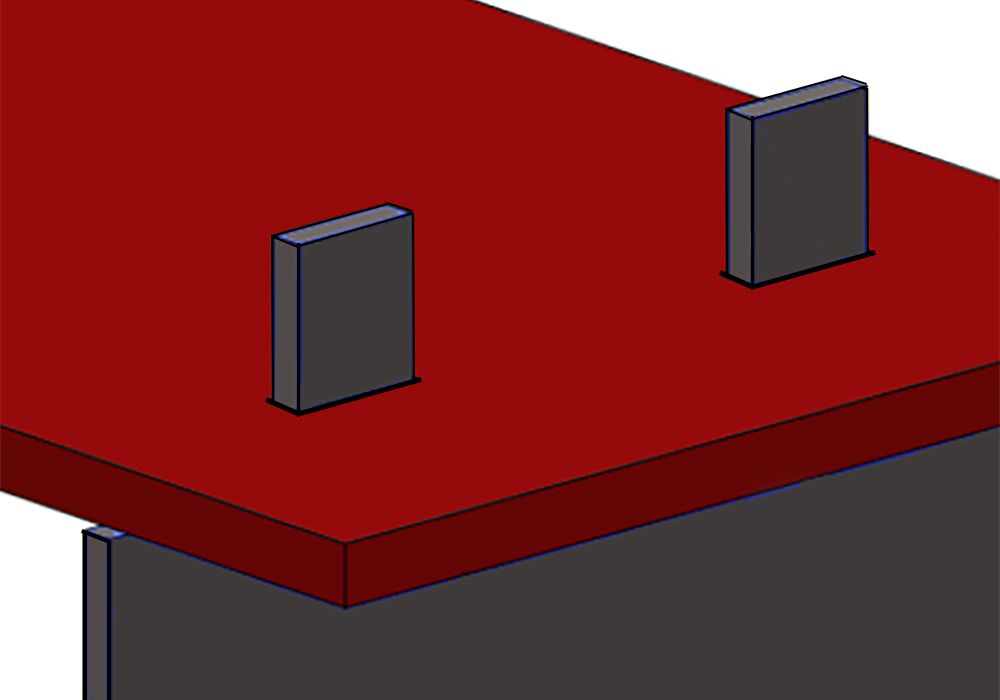

Booth enclosure construction is self-supporting with traditional assembly methods consisting of 18 gauge panels and 14 gauge floor channel, tie in angle, corner angle and tee bar. 5’16”-18 X ¾” long slotted truss head machine screws and heavy hex nuts are used to maintain a smooth booth interior. Bolted assembly on six inch centers ensures proper mating of companion flanges, channels and angles. Booth and enclosure assemblies are free standing with integral structural support.

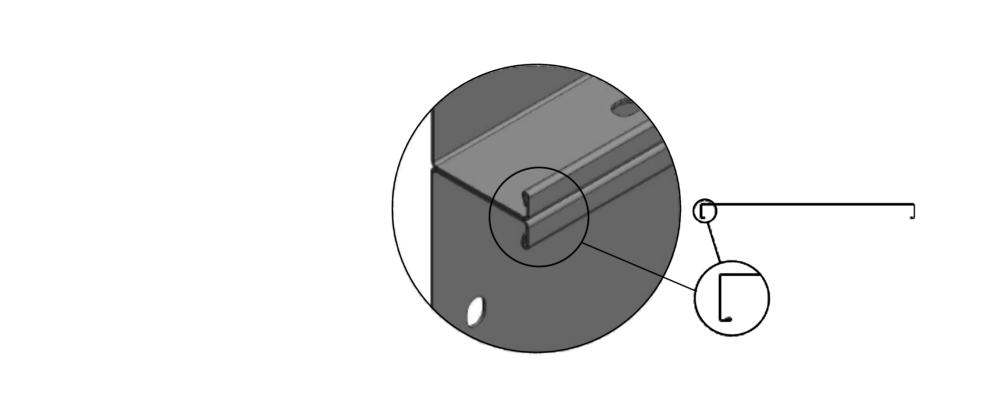

Safety Edges

Production Systems’ new safety companion flange feature a ‘tear drop safety edge’ which gives the panel more strength and rigidity while eliminating sharp edges.

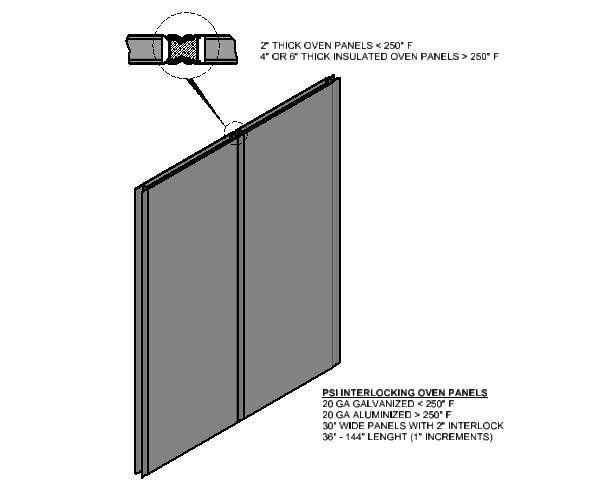

Insulated Oven Panel Assemblies

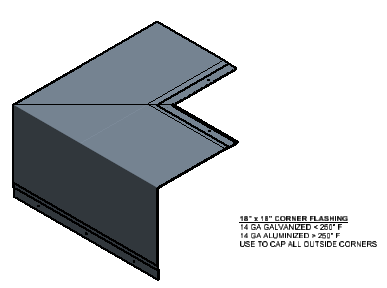

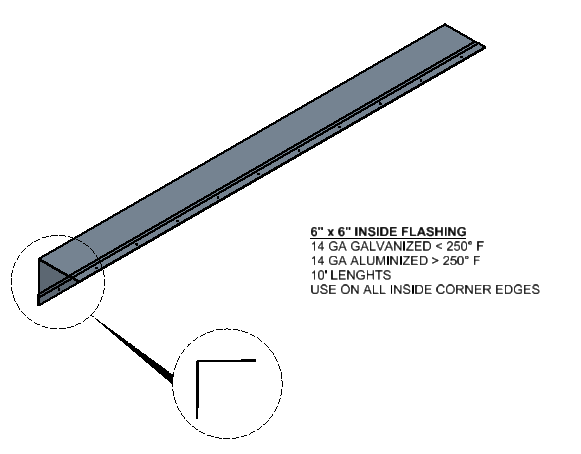

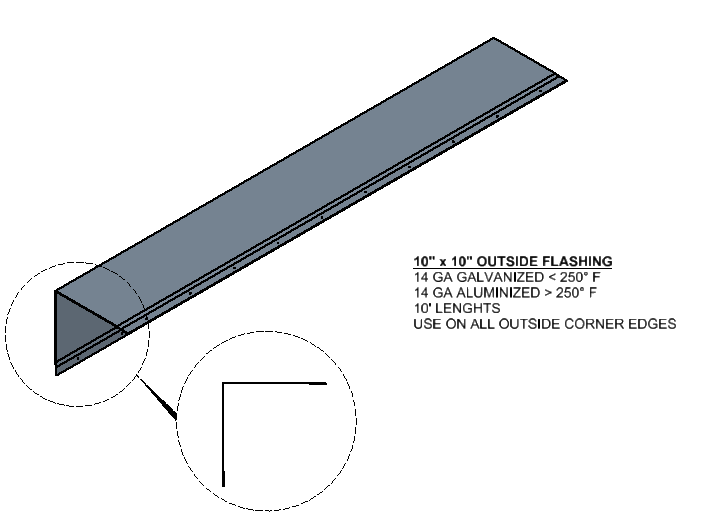

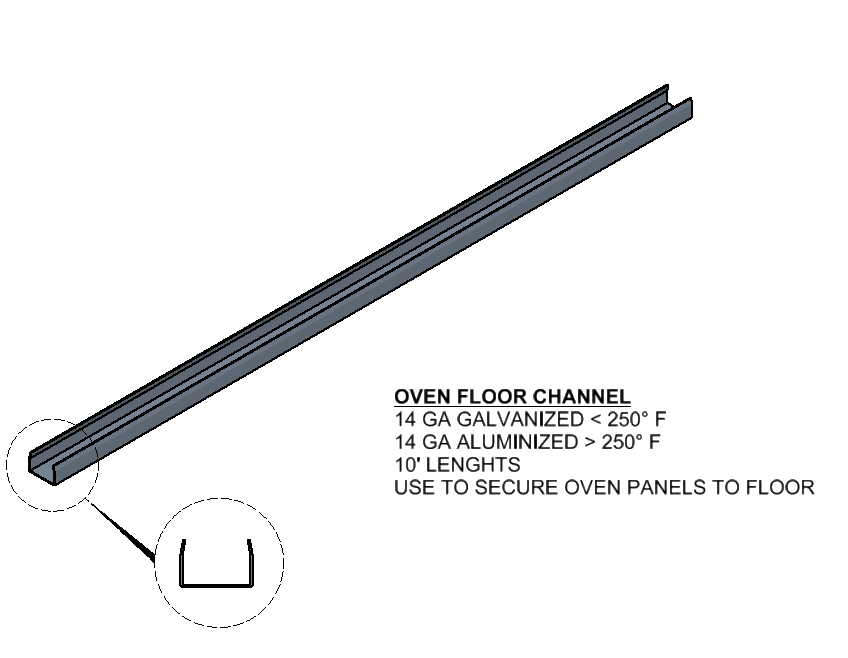

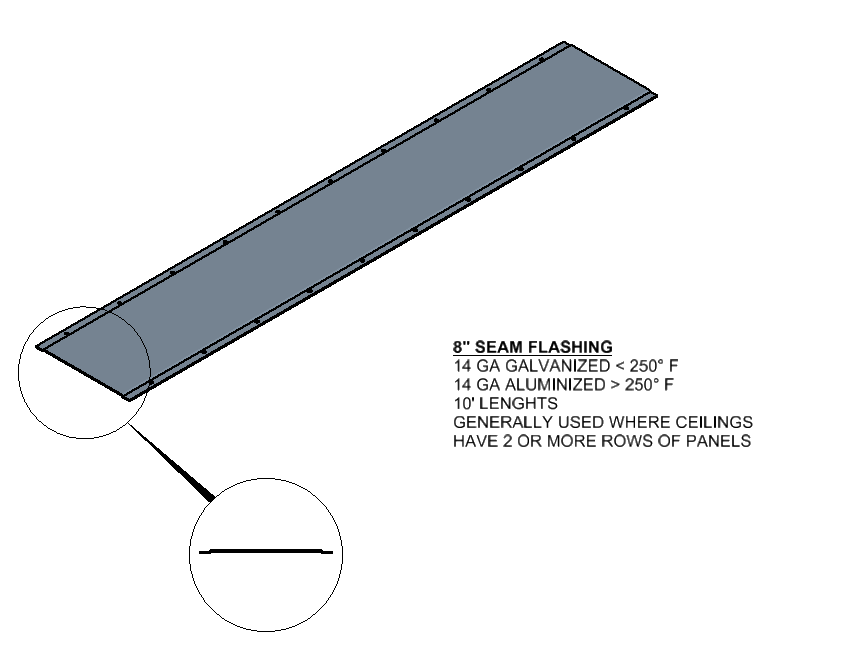

The main body of oven designs may be constructed of our standard tongue and groove interlocking oven panels, 2″, 4″ and 6″ thick, walls, floor and ceiling panels, consisting of #20 gauge aluminized steel inside and outside. The sheets are held together with space channels on ends and sides. The panels are internally insulated with Delta mineral wool insulation board, 4# to 8# density. All inside and outside corners of oven may be covered with #20 gauge aluminized flashing and attached to the panels with suitable heavy gauge sheet metal screws. Inside the flashing, fiberglass insulation may be tightly packed to prevent any heat loss from the seams at this point. The oven panels may rest on the floor secured in our floor channel. Conveyor and door openings may be cut and trimmed with our end cap.

Slot and Tab Filter Frame

Production Systems new Slot and Tab Filter Frame allows for much easier installation as the frame can be shipped broken down and easily assembled on site. Production Systems Knock Down Filter Frame Components slide together then tabs are bent to secure in place.

Components & Connections Articles

OPEN A DISCUSSION OR SCHEDULE A VISIT

(336) 886-7161