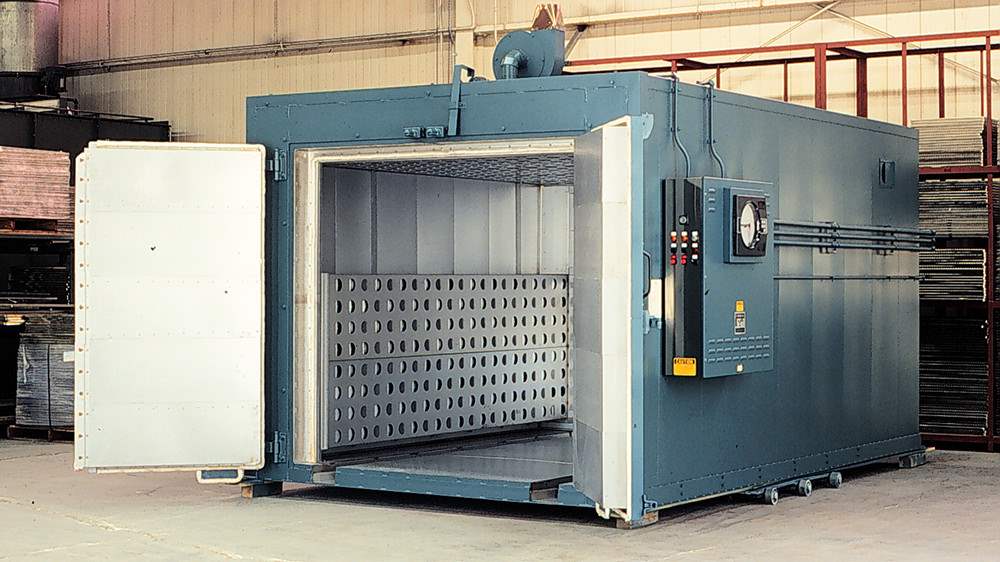

Like many equipment purchases, buying a process or batch oven for finishing involves considering a great many factors. Unlike industrial ovens, other purchases often can be installed in a facility without much interference with existing equipment. A process oven, however requires the analysis of factors, such as ventilation, clearance, and air circulation, in addition to determining the right size, location for the equipment, and budget parameters. In some instances, alterations to the infrastructure may be required. For example, exhaust and conveying systems must be routed through the facility and require a considerable amount of floorspace.

Ventilation and Exhaust

When considering the ventilation system, the air must come from somewhere and go somewhere. It must be filtered, heated and recycled.

Additionally, oven exhaust, if not handled properly, can introduce toxic fumes into your facility. Designing a system that exhausts safely can depend on the oven’s location and design of the building. An oven expert may need to visit the facility to make the necessary adjustments for optimal ventilation and exhaust design.

Air Circulation

Temperature consistency throughout the finishing oven is created by the proper air circulation and burner size and is critical to the oven’s performance. Eliminating cold spots and temperature variations in the oven ensures the part is heated uniformly reducing defects.

Recirculation systems and filters are used to combat dust and other particles that can negatively affect the paint’s finish. Consulting with a process engineer can be beneficial in evaluating air circulation and designing a system that reduces issues.

Floorspace

Exhaust and ventilation systems, as well as conveying and transportation systems, can take up a lot of floorspace. Consider the full footprint of the process oven including the secondary systems when deciding on an oven. Again, an expert can help in designing the complete oven system while being creative in the overall layout.

In conclusion, special attention is needed when deciding on a new finishing oven and the needed secondary systems. Ovens are much more than meets the eye. A professional with the experience and technical expertise is critical in assuring the decision process is done right.

Production Systems’ design and engineering team work with customers to determine the optimal oven design and including secondary systems. Based on the customer’s specific coating properties, our team will make sure proper air circulation, ventilation, and exhaust are achieved. In addition, we will help you evaluate the floorspace requirements and be creative in our approach. You may call us at (336) 886-7161, or email us at info@productionsystems-usa.com for more information.