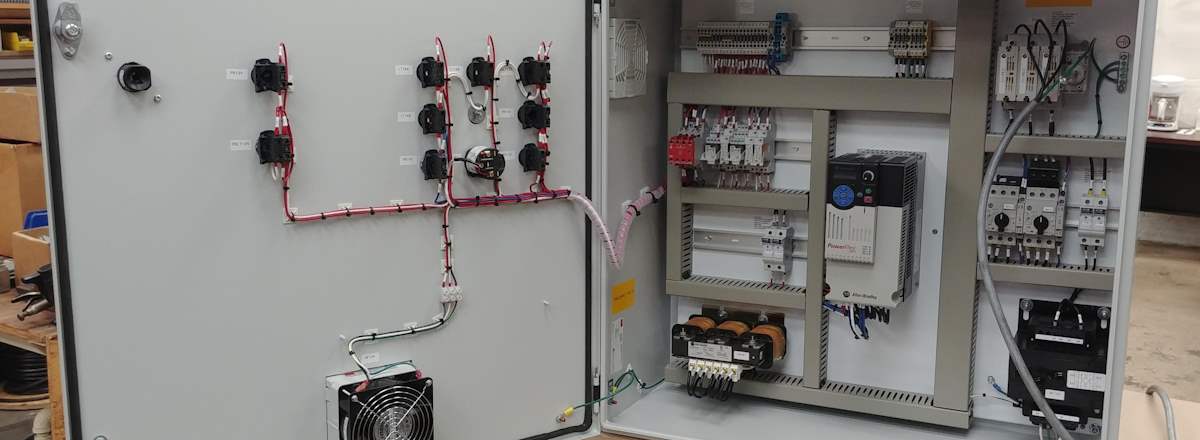

Production Systems’ most recent spray booth control panel is built with a fusible, lockable, rotary main disconnect with 100kA SCCR, allowing local electricians to easily attach main power to the panel. The control panel is housed in a “Type 12” listed electrical enclosure to provide maximum protection for all control components. Since this spray booth was designed to have operator-selectable variable speed exhaust, an active ventilation system has been incorporated to assure adequate cooling for the on-board variable frequency drive, (VFD).

Branch circuits and control circuits for lighting and spray interlock wiring have been provided and documented within provided schematics for ease of field wiring. A unique spray gun hanger system has been provided to eliminate costly “classified location” wiring. Once the operator presses the “FANS ENABLE” button, the fans may be started and stopped from within the working area of the paint booth simply by removing the spray gun from the hanger or replacing it to the hook. Indicator lights on the control panel face provide basic useful information concerning the start/stop status, exhaust air status, light lens status, and motor status. Power for the lighting circuit is provided from the internal control transformer operating at 120 volts AC.

A 3-way compressed air valve is the pivotal portion of the booth safe-circuit, assuring there is adequate filtered exhaust and that all light lenses are secure before opening to provide air for the spray operation.

Learn more about the many types of spray booths offered at Production Systems. You may also call us at (336) 886-7161, or email us at info@productionsystems-usa.com for more information.