It is important to carefully consider what heating system will be needed before making a paint booth purchase. There are various factors that should be considered in order to make sure a wise investment is made.

Consider the following when purchasing a paint booth and oven system:

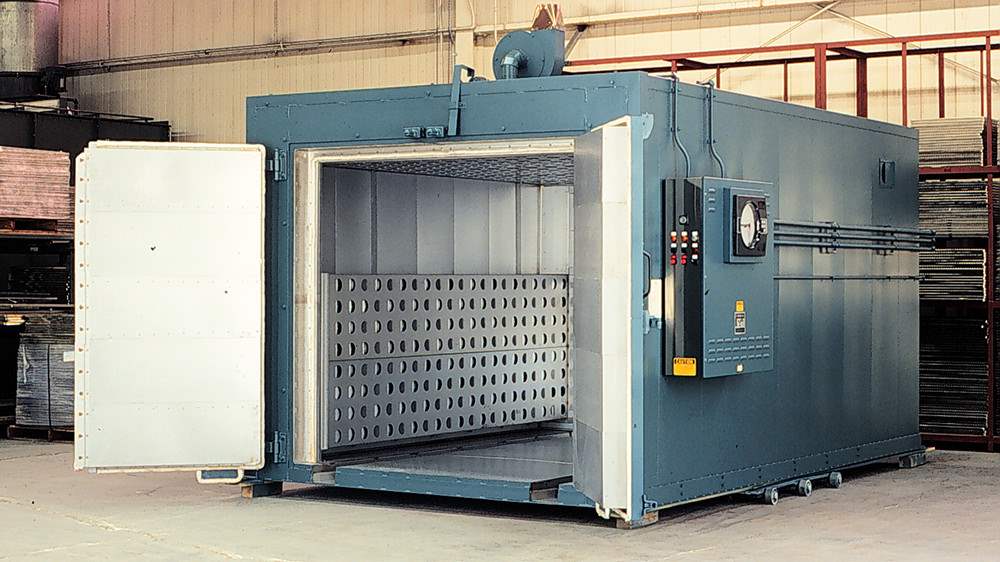

- An oven often requires alterations to the plant’s infrastructure. Understanding the requirements can keep you from wasting money in the long run.

- The exhaust system from the oven may need to be routed through the facility and may require a considerable amount of floorspace.

- In some instances, installing a heating system may require major modifications and can be quite expensive; for example, adding heating to a cross air-flow booth.

- Some booths, such as vertical air flow booths, are more easily modified to add heating; however, exhausting it may require a more complex route due to its rear evacuation and need for additional duct work. This may end up being more expensive.

- If you decide to purchase an unheated booth with the thought of adding heat down the road, make sure to leave space all around the booth. And don’t forget to evaluate your plant’s power supply and authorization from your local government.

- If your plant’s production volume is high, recycling heat can provide significant savings. Make sure to consider this at the beginning of your purchase cycle.

- If the volume of the parts to be painted is large, consider recycling heat as you will save a significant amount.

Keep in mind that the least expensive paint booth can become the most expensive after it is customized and upgraded, so it is critical to consider all the options early on in the cycle. Production Systems can help evaluate and determine what are the best paint booth and heating system options for your company’s needs. Contact us and consult with our engineers to learn more.