People often get industrial ovens and industrial furnaces confused. Both types of ovens provide high temperatures, both are housed in fireproof enclosures, and both are used for heat treatment in various industries. The major difference between the two, however, is simple – the temperature of the heat they provide. But there are other differences as well.

Temperature

The most notable difference between an industrial oven and furnace is the temperature. An oven operates at temperatures up to 1000 degrees Fahrenheit. A furnace heats to temperatures above 1000 degrees and can go to 2000 degrees or higher.

Heat Sources and Distribution

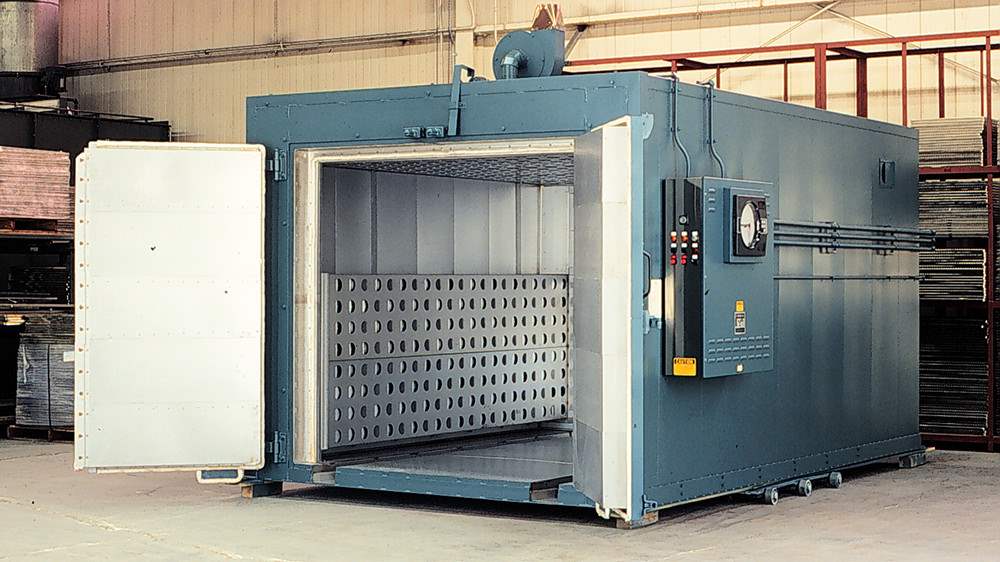

An industrial oven contains a chamber where the product is held and a separate chamber for the heat source and air recirculation fan. The air is heated then recirculated into the chamber holding the product, using a system of ductwork. A large amount of air is needed to transfer the heat to the product.

In an industrial furnace, the heat is introduced directly to the chamber where the product sits. The heat source can be gas, electric, steam, or hot oil. Depending on the heat source, various configurations are used to achieve uniform heating. In gas furnaces, the product sits on structural piers and burners are situated above and below the product. With electric furnaces, heating elements are located on the sides of the chamber and emit heat to the product.

Construction

Ovens are generally constructed with 18- or 20-gauge sheet metal, inside and out. Three-inch thick mineral wool-like insulation is used for lower temperatures and six-inch thick for temperatures above 500 degrees Fahrenheit.

Furnace exteriors are made with 0.1875-0.5-inch-thick steel. Insulation is either a ceramic blanket, ceramic modules, or refractory brick, and is eight to 12 inches thick. The steel exterior helps the shell maintain its structure.

Applications

Since industrial ovens operate at lower temperatures, the applications are those of low temperature operations, such as drying, curing, and cooking. The high temperatures of furnaces make them good for higher temperature applications, such as annealing, tempering, and carburization. Furnaces are often linked to the heat treatment of metals and other heavy materials, due to their high temperature capability.

Conclusion

The engineers at Production Systems are experts in industrial ovens, their features, and benefits. They can help you choose the right equipment for your specific processes. We will evaluate your application and make sure you don’t go wrong. Contact us to learn more about how we can help you.