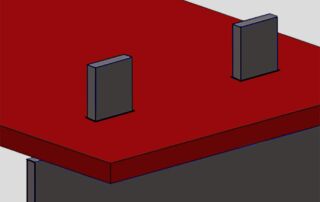

Spray Booth Panels With Safety Edges

Production Systems offers single skin, 18 gauge, galvanized steel panels for booth enclosures featuring a safety edge. The standard width of these panels are 24", 30" and 36" and the standard lengths are 30" to 144" in 6" increments. All panels feature Production Systems' exclusive safety edge. The new safety companion flange feature a ‘tear drop safety edge’ which gives the panel more strength and rigidity while eliminating sharp edges. Production Systems design, fabricate, and install many different types of finishing systems for many different industries. We also supply various components and connections for both, spray booth panels and oven panels. Visit our website to view spray booth panel pricing and get a formal quote.