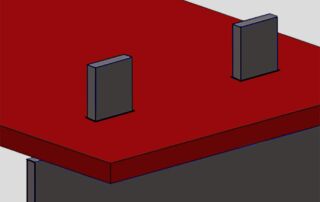

Production Systems Incorporates Slot and Tab Features Into Our Frame Designs For Easy Installation

Steel structures used in industrial environments are being designed to incorporate features that innately guide components into their correct positions during assembly. Known as ‘self-fixturing,’ this slot and tab design simplifies assembly and minimizes the need for adjustment. It basically makes assembly much quicker and easier, with minimal tools. And the structure stays the way it’s supposed to. Today’s machining technology has made it possible to design and produce components with slots and tabs. A few decades ago, when steel was cut using a shear press, this was not possible. New machines, such as the CNC and laser tables, have made this an option. In addition, only a few years ago, Solidworks introduced a “tab and slot” feature in their design software. This upgrade made the process of adding these assembly features quick and easy for designers. Self-fixtured steel designs assure that components when assembled align properly to each other. However, every tab or slot carries multiple stress concentrations, and when added to a steel component, there is a risk of disrupting the stress flow and creating high stress areas. [...]