For professional results in powder coating, choosing the right type of curing oven is essential. A high-quality curing oven will produce superior results, as well as save money in energy costs. There are many options in powder coating ovens, each with their own set of advantages and disadvantages.

The two main types of powder ovens include infrared and convection curing. The main difference between these two ovens is how they work.

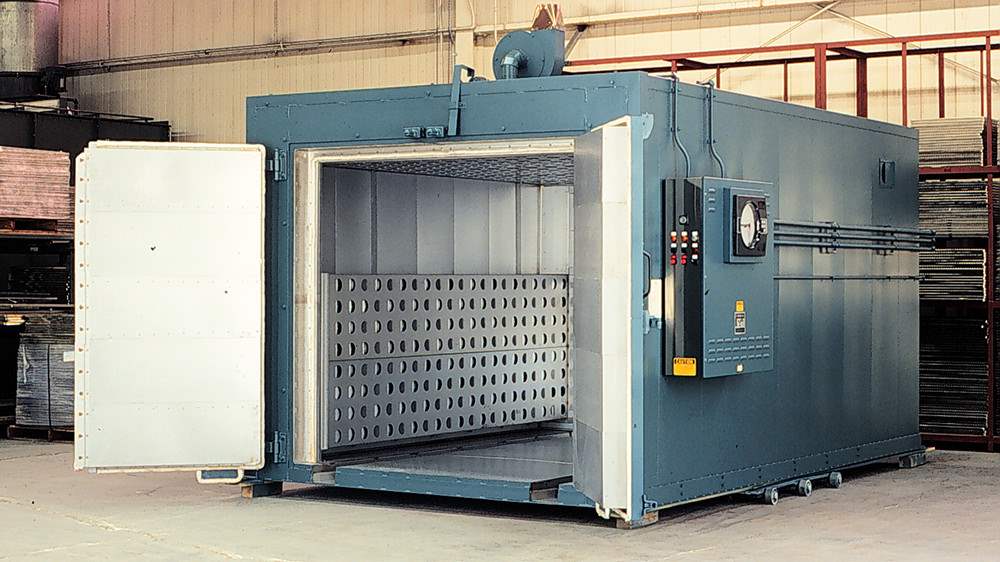

Convection Powder Coating Ovens

Convection ovens use convection heat, transferred through the air, to increase the temperature of the oven and the product surface. Curing in a convection oven starts on the outside of the product and works in. This outside-in method means it takes longer to cure the powder coating than it would with infrared. Due to the longer process, convection ovens are more often used for small production shops. But because convection ovens cure slower, they generally cost less than infrared ovens to purchase.

There are two types of convection ovens: electric and gas-powered. Electric ovens usually have smaller variation in temperature control and cost less to purchase. Gas convection ovens are more expensive to purchase but less expensive to operate.

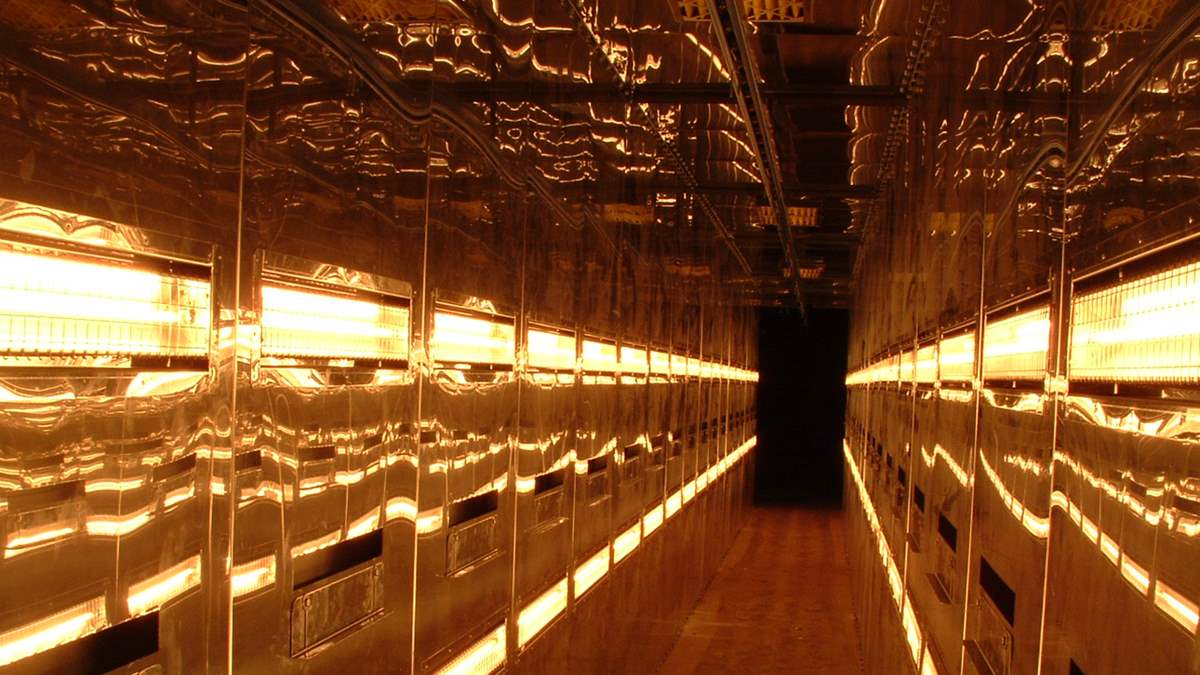

Infrared Powder Coating Ovens

Infrared powder coating ovens use radiant heat to cure the coating on a product. Heat from an infrared oven transfers directly to the product and cures the coating from the inside out. This is a much faster process than curing with convection ovens. Although there are some limitations to what the infrared waves can reach, the speed with which they work is the main reason they are more expensive to purchase. And for this reason, infrared ovens are often used for large production runs.

Class A and Class B Powder Coating Ovens

Once you have determined what type of oven is right for your facility, you will need to evaluate what ‘class’ you will need. The difference between Class A and Class B ovens is in the level of safety requirements provided. Class A ovens meet more stringent requirements. If your plant involves explosive, combustible, or volatile materials, Class A will be required. Class B ovens are usually fine for powder coating applications unless additional curing with liquid coatings is done. Your local authority can help you make this determination.

Other Powder Coating Oven Considerations

When evaluating powder coating ovens keep the following in mind:

Insulation –the operating efficiency of a powder coating oven is greatly determined by the insulation. 4 lbs. of insulation is a minimum amount.

Ductwork – Hazardous substances are removed from curing ovens through ductwork. Additionally, ductwork in convection ovens recirculates the air through the oven. This provides consistent uniform heating. So, it is important to learn about the ductwork when choosing a curing oven.

Heavy gauge steel construction – A good oven will be constructed from 16-gauge steel, at least; and the connecting channels from 18-gauge or more. This is extremely important because thicker steel will provide more insulation, higher efficiency, and better temperature control.

Safety features – It goes without saying that you will need to make sure the curing ovens in your plant include the safety features your specific facility needs.

Having an understanding of the different types of powder coating ovens can be very beneficial when deciding on an oven for your coating facility. Working with a knowledgeable company that can assist in the selection and design process is critical. Production Systems can help your company determine what powder coating oven is right for your production facility. Contact us and let us know what your needs are. We will make sure that your oven will work well for the surface that needs to be coated.