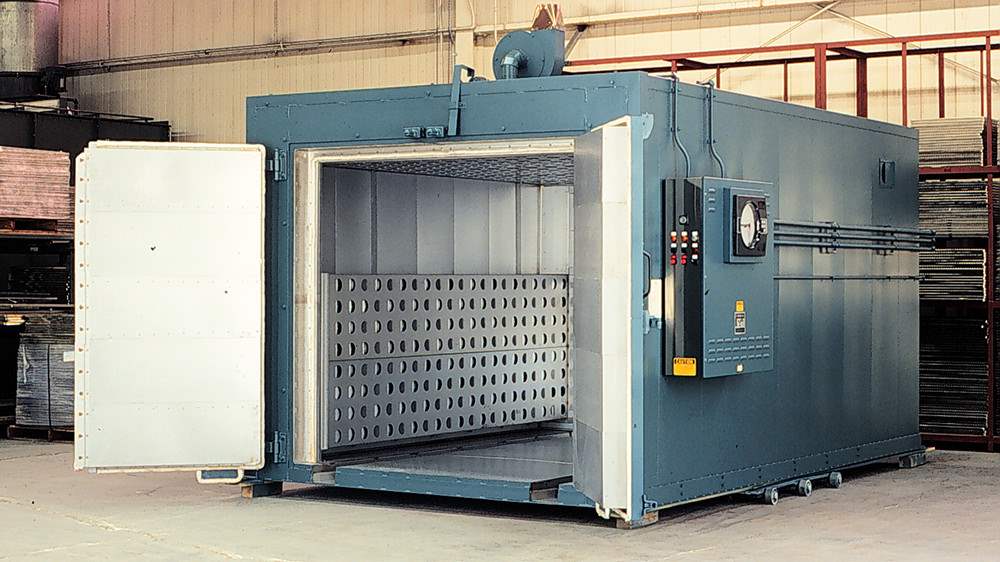

Production Systems works with manufacturers and finishing companies to design industrial ovens that meet the specific requirements of the groups. The engineering and design team at Production Systems incorporate the proper air circulation, ventilation exhaust, air seal, combustion equipment, safety controls, temperature controls, and electrical controls that are necessary for a successful process.

One of the primary factors in designing an industrial oven is the selection of the right materials. Initial considerations include the interior and exterior metals. When choosing materials for an industrial oven, temperature and corrosion are key considerations.

Material Options for Industrial Oven Walls

Industrial oven walls must be durable, resistant to high temperatures and corrosion, and provide effective insulation to maintain consistent temperature and energy efficiency. They also need to be designed to prevent warping and heat loss.

Heavy gauge cold rolled steel is often used for structural components, including industrial equipment. Due to the cold rolling process, this steel exhibits these properties: improved hardness, resistance to deformation, and greater tensile strength. It also produces smooth, high-quality surface finish, that makes it aesthetic pleasing.

Another material, coated aluminized steel has a temperature range that reaches 1100° F, is highly resistant to corrosion from moisture and heat, and requires very little maintenance. This makes it another top choice for ovens.

Stainless steel, boasts a range of properties including high corrosion resistance, the ability to withstand high temperatures, strength, durability, and an easily cleanable surface. It is a perfect material for many applications, including corrosive environments. Its attractive appearance also contributes to its popularity

Oven Insulation

In between the exterior and the interior walls of an industrial oven is insulation that ensures the oven heats to the required temperature. Though industrial ovens must operate at extremely high temperatures, the exterior of the oven needs to remain cool. High quality insulation of the proper density and compressed is added into the oven panels helps to prevent heat loss and allow minimal heat transfer to the exterior.

A few common materials for industrial oven insulation are mineral wools, such as glass wool and rock wool. Glass wool is made from glass and is also known as fiberglass. Rock wool is made from volcanic rock. These materials offer high thermal resistance; they also display resistance to chemicals and moisture.

Materials for the Ductwork of an Industrial Oven

Industrial oven ductwork includes supply ducts and return ducts. They are the network of pipes and channels that circulate air within and around the oven to dry products, heat materials, or cure coatings. These ducts are designed to provide even heat distribution and maintain specific temperature levels.

Ducts are typically made of materials like stainless steel or galvanized steel, chosen for their ability to withstand high temperatures and potential corrosive environments. Ductwork can be customized to accommodate specific oven configurations, product sizes, and process requirements.

Production Systems designs and engineers industrial ovens that operate at extremely high temperatures. The ovens offered by Production Systems are made from the right materials for the specific purpose, whether that is to heat treat parts, metals, and components for drying, curing, testing, or coating. Contact us to learn more about our industrial ovens and how we can help your company improve drying and curing processes.