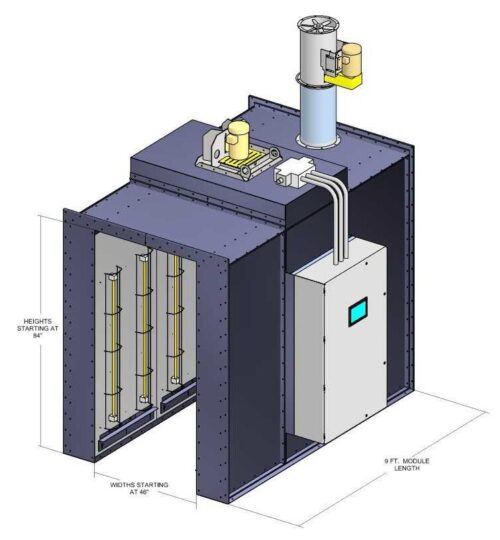

Standard 9’ Infrared Oven Module

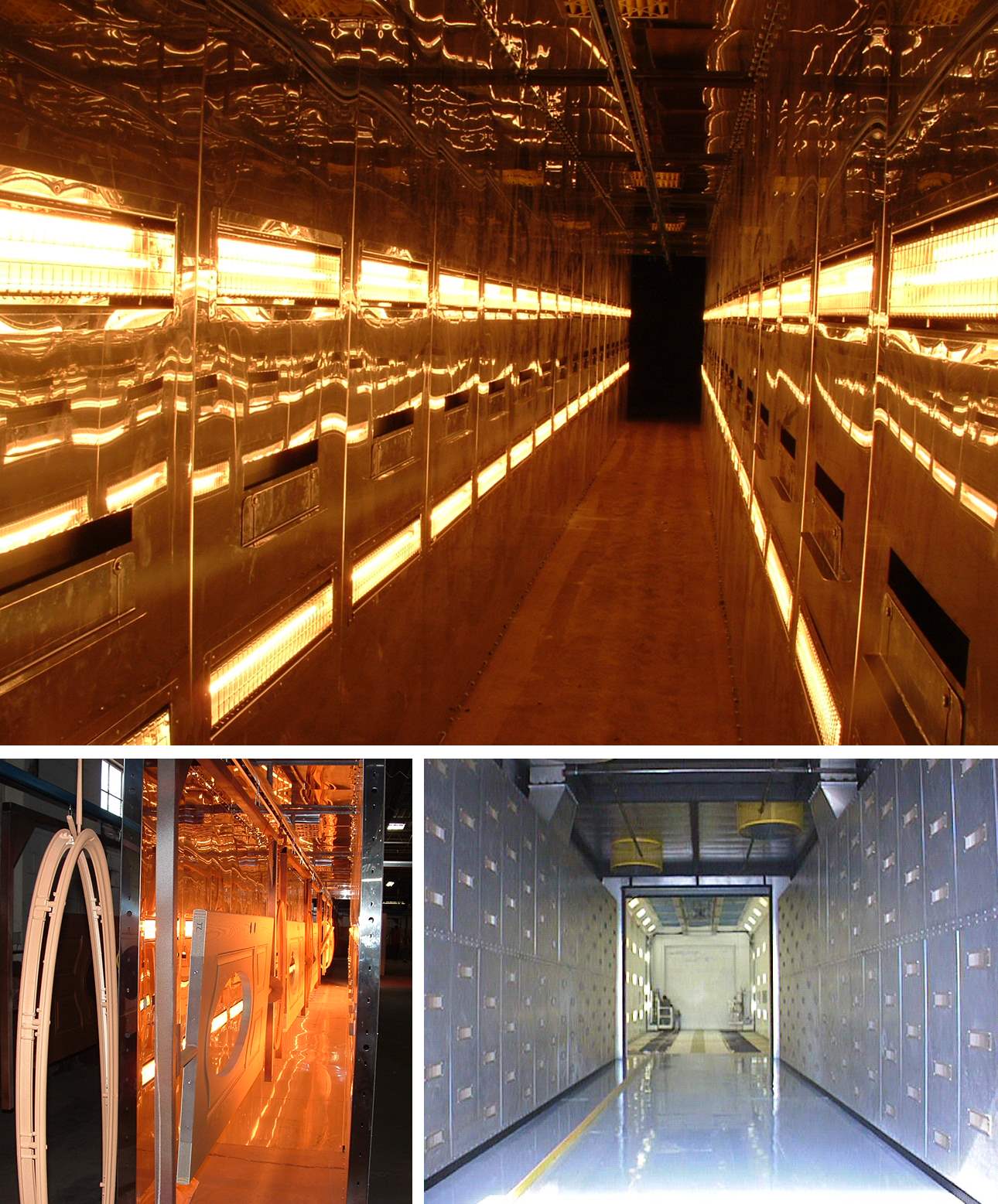

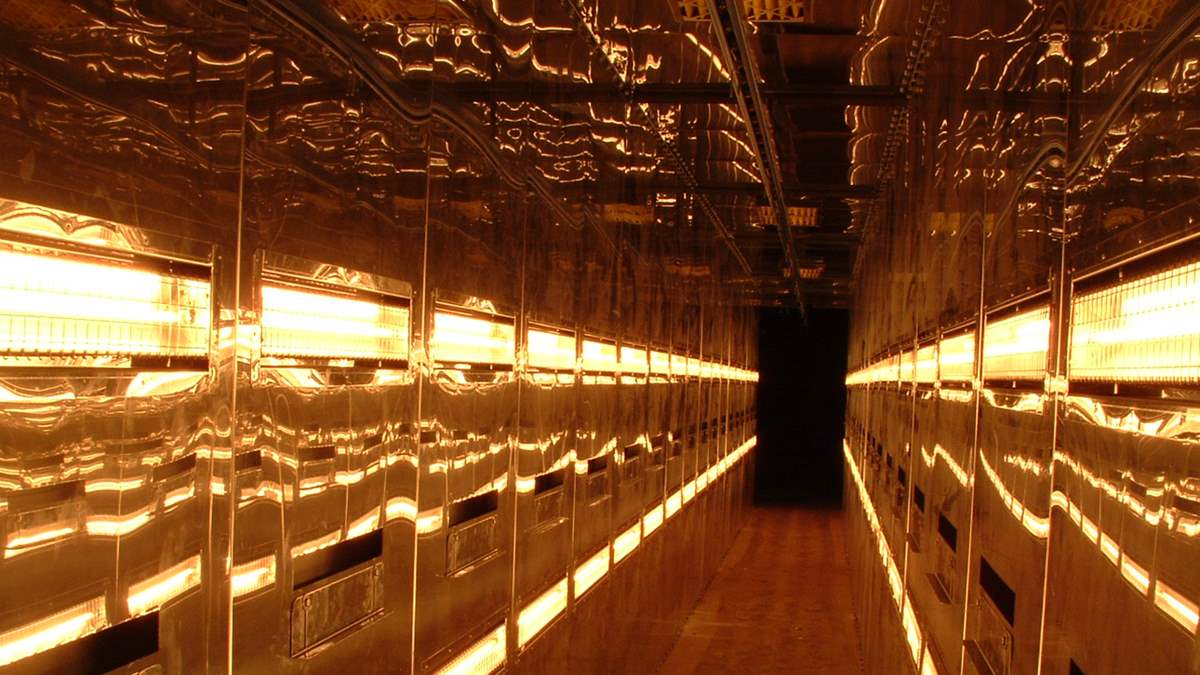

Production Systems superheat halogen cure ovens are designed to cure any coating. Pre-assembled and wired modules are tested onsite. Featuring a 9’ heated length with adjustable circulated air discharge slots, the oven is ideal for any finishing operation. All ovens come with a circulation and exhaust fan, UL508a listed control panel, and Allen Bradley 1400 PLC controller with a 7’’ touch screen. Vertical halogen infrared lamps with lamp holders are installed with 56’’ heated lengths. All ovens can be modified for a single zone batch operation or dual zone process operation. Widths starting at 42’’ to meet all finished good sizes.

Starting at $39,995

Industrial Powder Coating Ovens, Process & Batch Ovens, and Process Enclosures

Production Systems’ design and engineering team will work with our customers and coating suppliers to find the optimal oven design for your specific finishing requirements. Based upon coating properties our skilled team will make sure proper air circulation, ventilation exhaust, air seal, combustion equipment, safety control, temperature control, and electrical control are provided.

Types of Ovens

- Ambient, forced flash and cooling enclosures

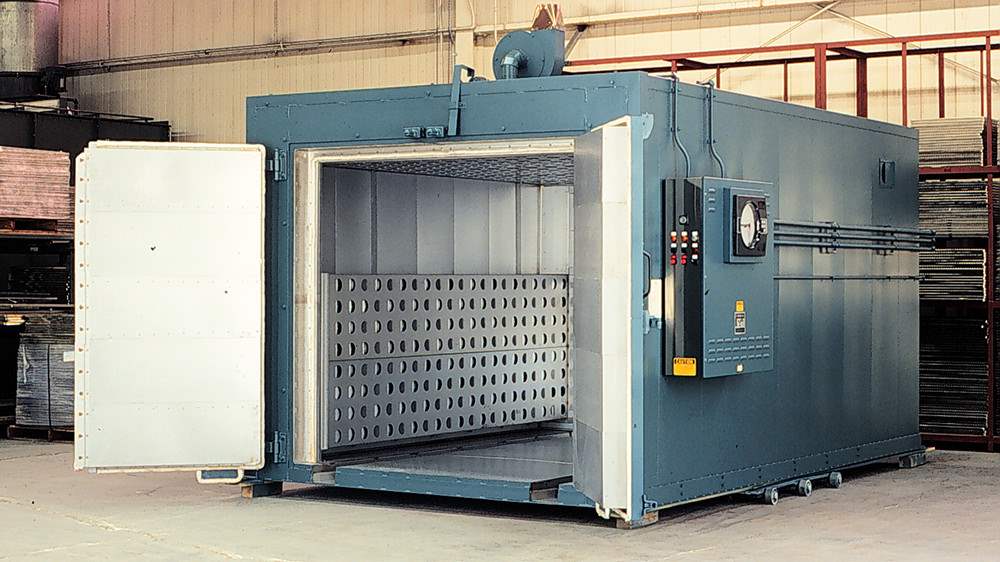

- Low and medium high temperature process and batch ovens

- Liquid water or solvent based coating cure ovens

- Powder coating cure ovens

- Hot water and steam heated ovens

- Gas fired ovens, overhead circulating fans for turbulent air flow, convection type with circulating fans, supply and return ducts, high velocity impingement type discharge duct

- Halogen / convection ovens with horizontal or vertical emitters, zone controls for hang lines, tow lines or flat lines.

- UV (ultraviolet) ovens

- Burn off ovens

- Gas catalytic ovens with integrated gas catalytic emitters and controls