Industrial finishing systems are routinely used in the door manufacturing industry. These door finishing systems are designed to provide a high-quality, durable and aesthetic coating for various types of doors. These systems can include spray booths, curing ovens, conveyor lines, dust collectors and other equipment that are tailored to the specific needs and requirements of the door manufacturer. Some of the benefits of using door finishing systems are:

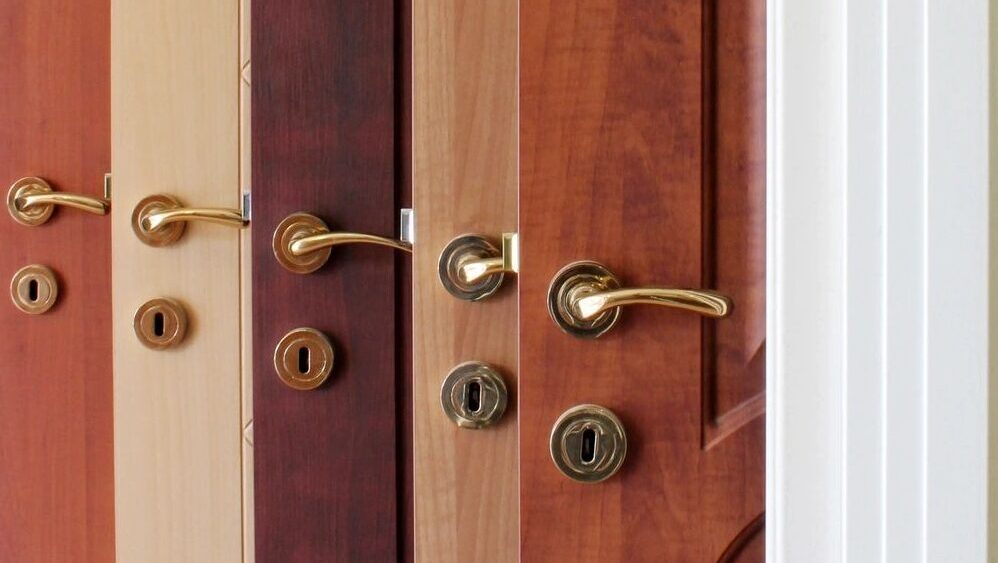

- They can handle different materials, such as wood, metal, fiberglass, composite and plastic, and apply different coatings, such as paint, stain, varnish, lacquer and polyurethane. This allows the door manufacturer to offer a wide range of products with different styles, colors and finishes.

- They can improve the efficiency, productivity and profitability of the door manufacturing process, by reducing waste, energy consumption and labor costs. They can also increase the output and quality of the finished doors, by ensuring a consistent and uniform coating application.

- They can enhance the appearance and performance of the final product, by providing a smooth, glossy and resistant surface that protects the door from scratches, stains, moisture and UV rays. They can also extend the lifespan and durability of the door, by preventing corrosion, warping and cracking.

Production Systems offers door finishing solutions that are tailor-made to the needs and requirements of the door manufacturer. Our experienced professionals can help you determine the best door finishing machines to improve productivity, efficiency and quality. We manufacture industry-leading equipment with premium-grade components, contact us to learn more.