Control Panels & Spray Booth Controls

At Production Systems Incorporated, we are proud of our custom-built products. From simple exhaust ventilation enclosures to fully automated finishing lines, we strive to provide our customers with systems that are dependable, user friendly and easy to maintain.

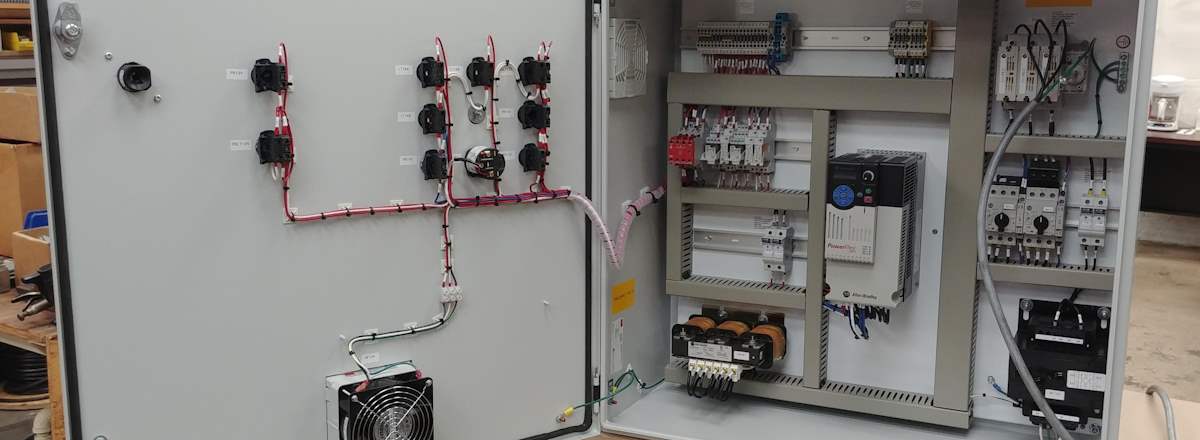

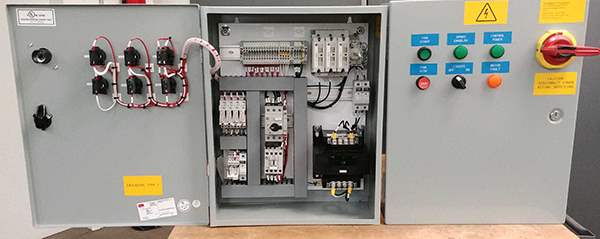

An important part of these systems are the electrical controls. Production Systems is a member in good standing with the National Fire Prevention Association (NFPA) and Underwriters Laboratories (UL). All electrical controls are built in compliance with UL 508A Standard for Enclosed Electrical Control Panels.

We utilize Allen-Bradley/Rockwell components in our panels based on performance, reliability and ease of replacement in the rare event of failure. We will, however, build according to our customers’ preferences. We have 40 years of experience in fabricating industrial electrical controls. We build from simple pushbutton, relay, and timer logic to programmable logic controller (PLC) and Human Machine Interface Screens (HMI) controlled systems that are network compatible.

All control design work is done on-site at Production Systems in close collaboration with the customer’s input and a seasoned engineering staff to guide the system design process. We use what we believe to be the best materials to create a durable and functional part of our customers’ manufacturing process. All drawings and layouts are submitted for our customer’s approval before beginning fabrication.

Our control panels are built with rotary fusible, lockable, main disconnects. This allows local electricians to easily attach main power to the panels. All branch circuits and control circuits are documented within provided electrical schematics. Controls are built and arranged in environmentally compatible enclosures.

All controls are pre-tested at our facility and bear a UL Label.

Control Panel News Articles

OPEN A DISCUSSION OR SCHEDULE A VISIT

(336) 886-7161